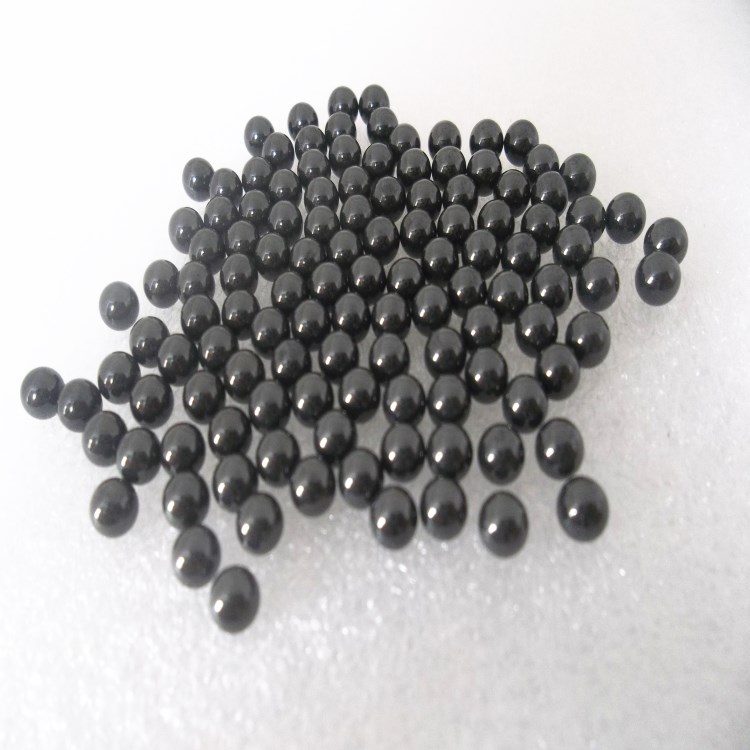

New Delivery for 11/32inch Bearing Chrome Steel Balls - 12.G1000 High hardness bearing steel balls for grinding and polishing – Kangda

New Delivery for 11/32inch Bearing Chrome Steel Balls - 12.G1000 High hardness bearing steel balls for grinding and polishing – Kangda Detail:

|

Parameter |

Product details |

|||

| Product Name: | Bearing steel ball / Chrome steel ball / Steel ball for bearing | |||

|

Material: |

AISI52100/ GCr15/ 100Cr6/ SUJ2 | |||

|

SIZE: |

G5 |

G10 |

G40-G200 |

G1000 |

|

2.381mm-15.875mm |

0.8mm-31.75mm |

4.763mm-100mm |

1.0mm-200mm |

|

|

HardnessHRC: |

0.8mm-30.0mm |

30.0mm-50.0mm |

50.0mm-200mm |

|

|

61-66 |

60-65 |

58-64 |

||

|

Production Standard: |

ISO3290 2001 GB/T308.1-2013 DIN5401-2002 |

|||

Product features: bearing steel balls have high hardness, high precision, wear resistance and long service life;

Oily packaging, ferritic steel, magnetic;

Application areas:

1. High-precision bearing steel balls are widely used in high-speed silent bearing assembly, auto parts, motorcycle parts, bicycle parts, hardware parts, drawer slides, guide rails, universal balls, electronics industry, etc.;

2.Low-precision bearing steel balls can be used as grinding and polishing media;

|

Chemical composition of AISI52100 bearing steel balls(GCr15/SUJ2/100Cr6) |

|

| C | 0.95% –1.10% |

| Si | 0.15%–0.35% |

| Mn | 0.25%-0.45% |

| P | 0.025% max. |

| S | 0.025% max. |

| Cr | 1.35% –1.65% |

| NI | 0.03%Max |

| Mo | 0.1%max |

Bearing steel has high hardness, tensile strength, contact fatigue strength and wear resistance, and considerable toughness, which meets the requirements for corrosion resistance and high temperature resistance under certain conditions.

The high carbon chromium bearing steel has a high carbon content (0.95-1.05%), high and uniform hardness can be obtained after quenching, and a long fatigue life. The disadvantage is that it is slightly less resistant to large loads and impact toughness.

High-carbon chromium bearing steel is mainly used as the rings and rolling elements of rolling bearings under general conditions of use.

Bearing steel balls, as an important part of the bearing, play a very critical role.

Therefore, the use effect and service life of the bearing are closely related to the accuracy and hardness of the bearing steel ball. The hardness of the bearing steel ball is related to the crushing load value of the steel ball.

| COUNTRY | STANDARD | MATERIAL NAME |

| CHINA | GB | GCr15 |

| USA | AISI | E52100 |

| JAPAN | JIS | SUJ2 |

| GEMANY | DIN | 1.3505 |

The biggest feature of the bearing steel ball is its high hardness and wear resistance. Then we need to be frequently exposed to the hardness value of the steel ball. The hardness value range of the finished steel ball is specified in the national standard of steel ball GB/T 308.1-2013.

Product detail pictures:

Related Product Guide:

We are convinced that with joint endeavours, the small business between us will bring us mutual benefits. We could assure you products quality and competitive selling price for New Delivery for 11/32inch Bearing Chrome Steel Balls - 12.G1000 High hardness bearing steel balls for grinding and polishing – Kangda , The product will supply to all over the world, such as: Latvia, Russia, Uzbekistan, In order to carry out our goal of "customer first and mutual benefit" in the cooperation, we establish a specialist engineering team and a sales team to supply the best service to satisfy our customers' requirements. Welcome you to cooperate with us and join us. We have been your best choice.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.