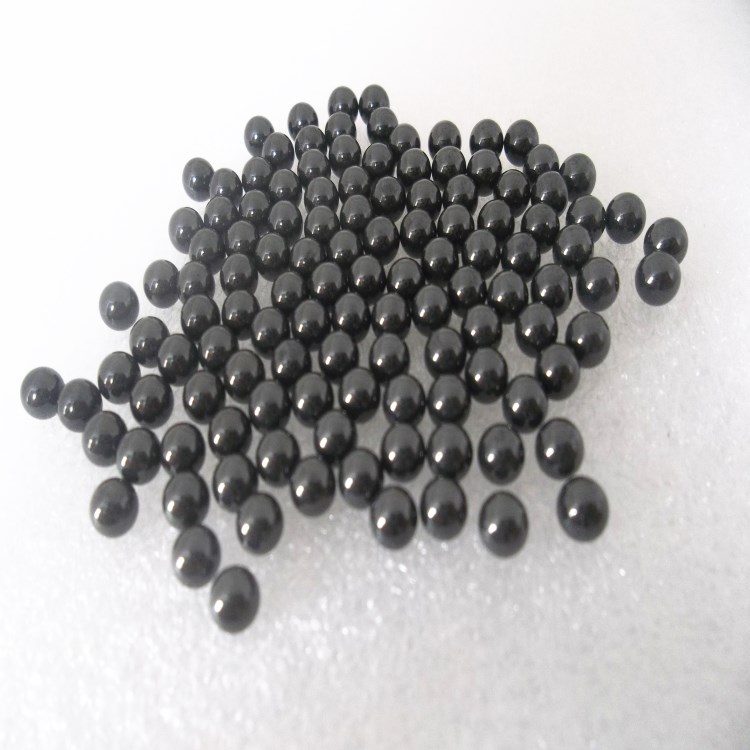

OEM Manufacturer 6mm Ceramic Bearings Ball - Si3N4 ceramic balls – Kangda

OEM Manufacturer 6mm Ceramic Bearings Ball - Si3N4 ceramic balls – Kangda Detail:

Silicon nitride ceramic balls have high strength, high wear resistance, high temperature resistance, corrosion resistance, acid and alkali resistance, and can be used for a long time in seawater, and have good insulation properties. Can cope with more complex use and working environment.

Si3N4 ceramic balls have high hardness and light weight. When used in many specific accessories or equipment, they have a smaller coefficient of friction and acceleration of gravity, resulting in less wear and extending the service life of the accessories.

Si3N4 ceramic balls are resistant to high temperatures and can work stably in a high temperature environment below 1200 degrees Celsius with small volume changes. Better thermal vibration performance, thermal vibration temperature is 900-1000 degrees Celsius.

It also has self-lubricating properties and can be used in environments where no lubricating medium is highly polluted. Become the material of choice for ceramic bearings and hybrid ceramic ball bearings.

Compared with steel balls, the main advantages of ceramic balls are:

(1) It is 59% lighter than steel balls, which reduces the centrifugal force, rolling and abrasion on the raceway when the bearing is running at high speed;

(2) The modulus of elasticity is 44% larger than that of steel, which means that the amount of deformation is much smaller than that of steel balls when subjected to force;

(3) Hardness is higher than steel, HRC reaches 78;

(4) The coefficient of friction is small, non-magnetic, electrically insulated, and more resistant to chemical corrosion than steel;

(5) The coefficient of thermal expansion is 1/4 of that of steel, which can withstand sudden temperature changes;

(6) The surface finish is better, Ra can reach 4-6 nanometers;

(7) High temperature resistance, the ceramic ball still has high strength and hardness at 1050 degrees Celsius;

(8) It will not rust and can work under oil-free lubrication conditions.

Product detail pictures:

Related Product Guide:

Our enterprise since its inception, usually regards product top quality as business life, repeatedly enhance manufacturing technology, make improvements to product excellent and continuously strengthen enterprise total high quality administration, in strict accordance with all the national standard ISO 9001:2000 for OEM Manufacturer 6mm Ceramic Bearings Ball - Si3N4 ceramic balls – Kangda , The product will supply to all over the world, such as: Italy, Latvia, Nigeria, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.